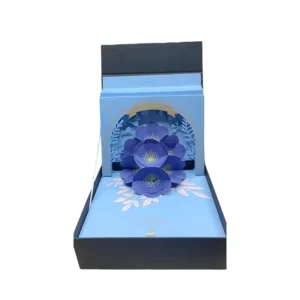

Handmade gift boxes are used in packaging various products such as jewellery, perfume, cosmetics, watch, food packaging, etc.

I. Design

We can design box shapes, materials, and printing content according to clients’ needs and concepts. We provide reference materials such as speciality papers based on clients’ requirements during the design process. The overall design aims to achieve process feasibility and controllability, increasing efficiency and reducing costs. A white sample of regular paperboard or cardboard boxes can be completed within one day, a white sample of handmade boxes within three days, and a coloured sample within five days.

II. Plate-making

Plate-making usually uses digital printing or CTP plate-making technology to convert the design into a printed template for subsequent printing operations. Plate-making needs to be confirmed and modified by clients until satisfaction.

III. Printing

Printing is one of the critical steps. Our factory just bought a new printing machine (Heidelberg printing machine) to meet clients’ high-quality printing requirements. In addition, we have UV printing machines, gold stamping machines, and silver stamping machines to meet the various demands of different processes. After printing, we need to confirm and modify by clients until satisfaction.

IV. Die-cutting

Die-cutting is a critical step. Professional cutting equipment ensures that the cardboard box shape, structure, and size meet the standard. In the process of die-cutting, relevant knives and die-cutting templates need to be customized according to the shape and size of the boxes to ensure precise and beautiful cutting. Usually, the handmade packages we produce include cylinder boxes, flip-top boxes, folding boxes, and hinged boxes. After die-cutting, the cut gift boxes must be inspected and trimmed to ensure they meet the required standards and quality.

V. Assembly

Assembly is the last step in the production of handmade gift boxes. We must perform corresponding operations during assembly according to the design and plate-making. After printing and die-cutting, the printed paper is cut, folded, and glued. To ensure the gift box’s appearance, firmness, and ease of operation, special attention needs to be paid to the folding, glueing, and assembly of the gift box. Our factory has automatic positioning machines, leather machines, and production lines. Usually, handmade boxes come with stickers, silk ribbons, ribbons, PVC transparent windows, magnets, hooks, and other accessories. After folding and assembly, the created handmade gift boxes must be thoroughly checked and sorted to ensure their quality and appearance.

VI. Packaging and Delivery

The production process of handmade gift boxes usually takes 10-12 days. Packaging aims to protect the gift box and make it more beautiful and delicate. During packaging, different materials are selected according to the client’s requirements, mainly including corrugated boxes, bubble bags, pearl cotton, punch boards, etc., which can better protect the outer packaging of the box. Finally, the high-quality and satisfied handmade gift boxes must be 100%QC tested and delivered to clients. Depending on clients ‘ requirements, delivery can be arranged by air or sea transport.

In summary, the production process of handmade gift boxes is very complex and cumbersome, requiring professional skills and experience to ensure their quality and beauty. High-quality and customized handmade gift boxes can be produced only by following strict procedures and standards.